What makes matco different?

At MATCO they are committed to keeping abreast of the latest technological advancements in the construction industry. They actively utilise these tools to deliver the productivity and value for money their clients have come to expect from them.

Equipment

MATCO believe their modern fleet of equipment provides industry leading productivity, efficiency and cost effectiveness. For example, both CAT and Scania brands utilised by MATCO are renown for the use of the latest power and hydraulic technologies to complete the job quickly, quietly and safely while at the same time being friendly to the environment via their modern emissions reduction capability.

MATCO, believe their well presented equipment actively demonstrates the pride, passion, and professional service they bring to their clients and their projects.

Minimal onsite downtime with MATCO

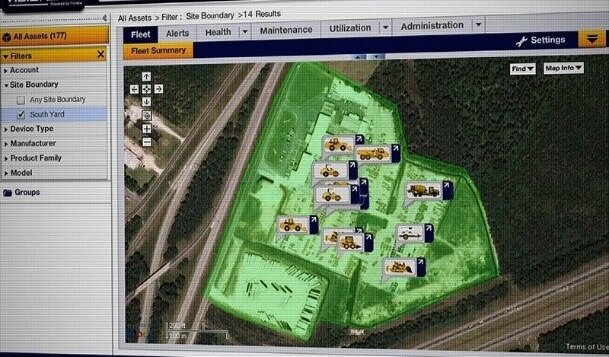

MATCO’s equipment repair and maintenance schedules are coordinated via GPS and remote monitoring meaning any downtime onsite is eliminated or kept to an absolute minimum for their clients.

2 Dimensional Technologies

MATCO's fleet of modern CAT 313FL excavators are equipped with CAT Grade control 2D depth and slope positioning. This provides their operators with real time bucket tip elevation guidance for flat or sloping plains – meaning they can provide a faster, more accurate final trim finish for their clients.

Their CAT 289D tracked skid steer is equipped with the SHARP GRADE precision laser leveller system - providing a quick setup and an extremely accurate final trim solution for your project.

3 Dimensional/GPS Technology

MATCO can provide both 3D or GPS final trim options for our bulldozer, grader, tracked skid steer and excavator equipment. They utilise both TOPCON and LEICA systems to deliver accurate subgrade and final trim results to their clients via their capable and experienced team of operators.

Their Leica 3D Total Station in particular, can provide stunningly accurate results for your project - resulting in decreased project cost for you via minimal product wastage.

Design/Surveying

Design solutions - Utilising their LEICA iCR80 Robotic Total Station survey equipment, their in house civil engineer can provide accurate measures of cut to fill/waste quantities and layout fully rendered 3D models in the field.

MATCO also utilise the services of an independent registered surveyor as and when required.

Flexibility

Their teams experience, capability and can-do attitude allows them to come up with tailor made solutions for their clients. MATCO pride themselves on providing a flexible, approachable and friendly service with a team that’s always willing to go the extra mile. From port work to palm kernel, big jobs or small, their team are there to assist you achieve positive outcomes for your business safely, professionally and on time.

Challenging Environments

High Stacking Grain

High Stacking Palm Kernel